Structure of the Smart-TPM Model: From Traditional Management to the Advancement of Emerging Technologies

By: Bristol (UK) Team

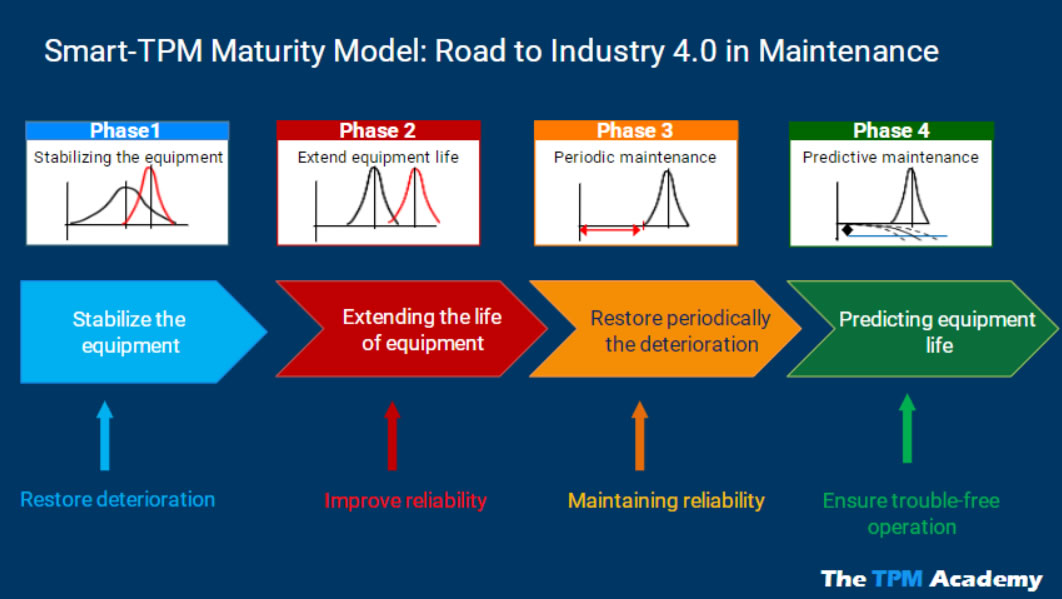

The Smart-TPM Maturity Model serves as a transformation guide for companies seeking to improve their maintenance systems. Rooted in the core principles of Total Productive Maintenance (TPM), this model adapts to the evolving landscape of Industry 4.0 technologies. Below is an outline of the strategy proposed by this model, which integrates traditional TPM practices with the progressive implementation of advanced technologies.

The model follows the four-phase approach originally proposed by Professor Nakajima for the development of efficient maintenance systems, incorporating advanced technologies at each stage in a gradual and structured manner.

Phase 1: Equipment Stabilisation – Traditional TPM Practices

The first phase of the Smart-TPM model focuses on stabilising equipment through traditional TPM methods. The primary objective is to eliminate the root causes of frequent failures and ensure stable, defect-free operations. This phase is critical for laying a solid foundation before introducing any advanced technologies.

In this context, traditional TPM tools such as failure analysis are employed to identify and eliminate recurring breakdowns. Autonomous maintenance is also introduced, empowering operators to perform basic tasks such as cleaning, inspection and lubrication, thus ensuring equipment runs reliably. Visual management systems are implemented to facilitate monitoring and control of equipment status.

This phase is fundamental to establishing a culture of reliability and continuous improvement, creating a work environment that prioritises equipment optimisation and prepares the organisation for the integration of more sophisticated technologies in later stages.

Phase 2: Prolonging Equipment Lifespan – Scheduled Preventive Maintenance

In the second phase, the focus remains on traditional methods, but with the explicit aim of extending the operational life of equipment. This is achieved by implementing a structured preventive maintenance schedule, including regular lubrication, replacement of worn components and calibration of machinery. As equipment becomes more stable and reliable, it is essential to follow a maintenance plan that prevents premature wear and unplanned downtime.

Ensuring the availability of spare parts and training maintenance staff to perform timely replacements is also a priority during this stage. The emphasis lies in maintaining the efficient operation of equipment for as long as possible without yet resorting to predictive technologies. The operational stability achieved here provides the foundation for future technological enhancements.

Phase 3: Improving Operational Efficiency – Integration of Industry 4.0 Technologies

Once the equipment has been stabilised and its lifespan extended, the third phase shifts focus towards enhancing operational efficiency through the introduction of Industry 4.0 technologies. At this stage, emerging tools such as smart sensors and IoT (Internet of Things) devices are deployed to monitor key variables in real time, such as temperature, vibration and pressure. This data-driven approach allows for the early detection of faults, enabling proactive and targeted maintenance interventions.

Big Data analytics and predictive platforms are used to process the data collected, offering precise insights into the condition of the equipment. In addition, machine learning (ML) algorithms help systems learn from historical data and recommend optimal maintenance timings.

This proactive approach increases productivity, reduces unscheduled downtime and optimises resource allocation, marking a significant step towards intelligent and efficient maintenance. With these technologies in place, operational performance improves, laying the groundwork for the final phase of transformation.

Phase 4: Predictive and Autonomous Maintenance – Advanced Technological Evolution

In the final phase, the Smart-TPM model evolves into a system of predictive and autonomous maintenance. Maintenance is no longer reactive or time-based, but instead anticipates failures before they occur, significantly reducing downtime and boosting operational efficiency. Digital twins play a central role in this phase.

Digital twins create virtual representations of physical equipment, enabling scenario simulation and behaviour prediction under various operating conditions. This technology helps optimise maintenance planning and facilitates data-informed decision-making.

Furthermore, the introduction of remote monitoring systems allows continuous supervision of assets, with the capability for remote interventions when required. As systems become increasingly autonomous, basic maintenance tasks can be executed without direct operator involvement. This not only enhances reliability and uptime, but also reduces human dependency, marking a key advancement in the journey towards intelligent maintenance.

Developing a New Work Culture: The Role of Traditional TPM Foundations

One of the primary reasons for starting with traditional TPM practices is the need to establish a strong, disciplined work culture. This shift involves more than technical changes; it requires a transformation in daily attitudes and behaviours. TPM fosters a culture of operator empowerment, where staff actively participate in maintenance by identifying and resolving issues on the shop floor.

This cultural foundation is vital for long-term success, as advanced technologies are unlikely to be effective without a workforce committed to ownership, responsibility and continuous improvement. Early-stage TPM practices such as autonomous maintenance and root cause analysis instil a proactive mindset in employees, reinforcing the importance of taking care of machinery and using resources efficiently.

Restoring Equipment and Selecting the Right Assets for Technological Integration

A further justification for initially focusing on traditional practices lies in the reality that many businesses still operate with old equipment not yet ready for technological overhaul. Here, Reliability-Centred Maintenance (RCM) plays a crucial role by helping determine which assets will truly benefit from Industry 4.0 enhancements.

RCM identifies which equipment is most critical to operations and where maintenance efforts should be concentrated. Only those assets that demonstrate high reliability and potential for long-term use are selected for technological upgrades. This approach avoids unnecessary investment in machinery that may not yield significant returns or cannot take full advantage of predictive or autonomous systems.

At the same time, working to restore older equipment maximises the value of existing assets. Not all machines require digital upgrades — some, especially those that are less critical or structurally robust, can continue to perform effectively with traditional maintenance methods. This strategy avoids excessive capital expenditure while ensuring that technological investments are targeted at the most strategically important equipment.

Technological Progression: A Phased Approach Based on System Maturity

Once the traditional maintenance foundation is securely in place and operational stability has been achieved, it becomes viable to begin integrating advanced technologies in a measured and systematic way. Not all assets will be suitable for this transition. Smart sensors, IoT devices and predictive analytics will be applied only to equipment that has proven to be stable and reliable, ensuring that technology is used to optimise rather than compensate for maintenance shortcomings.

This gradual shift to predictive and automated systems ensures that companies are not overwhelmed by the complexity of new technologies. Rather than applying a one-size-fits-all solution, a tiered strategy is adopted where critical and high-value equipment is prioritised for updates. Technologies are implemented only when the supporting processes and culture are mature enough to sustain them.

Conclusion

The clear and strategic separation between traditional and technological phases within the Smart-TPM model is both justified and essential. Early TPM phases serve to establish a robust maintenance culture, instil a proactive mindset and ensure that equipment is stable and fit for further enhancement. Without such a foundation, advanced technologies risk being underutilised or misapplied.

The use of RCM ensures that only the most suitable equipment is selected for Industry 4.0 integration, maximising return on investment and avoiding unnecessary spending on non-strategic assets.

By combining traditional methods with the gradual adoption of cutting-edge technologies, the Smart-TPM Maturity Model delivers a more reliable, efficient and sustainable maintenance system — one that is fully aligned with the challenges and opportunities of Industry 4.0.